AS9100D - ISO9001 - ITAR Registered - Military Critical

AS9100D - ISO9001 - ITAR Registered - Military Critical

Die cutting, CNC, Laser, Laminating services

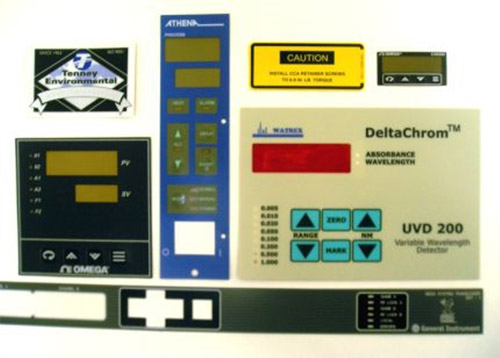

Our capabilities include laser cutting, die cutting, embossing, laminating, electrical and mechanical light assembly. Laser cutting is particularly attractive for rapid prototyping or for very complex shapes, while die cutting and embossing can provide low cost solutions for high volume production. Capabilities also include kiss cutting, marking, and perforating.

| Typical Applications | Printed Circuits/Electronics Graphic overlays Medical Parts Gasket Fabricating General Converting Rapid Prototyping Membrane Switches Signage |

|---|---|

| Materials | Polycarbonate Acrylic Polyester ABS Rubber & Silicone Foams Pressure-Sensitive Adhesives |

The choice of materials is a critical factor in achieving precision and durability. The selection spans a spectrum of versatile options, including polycarbonate for transparent and impact-resistant applications, acrylic for high optical clarity and weather resistance, and polyester for chemical resistance and dimensional stability. ABS brings a balance of strength and machinability, while rubber and silicone offer flexibility and resilience, particularly in applications requiring elasticity and extreme temperature resistance. Foams, in both closed-cell and open-cell variations, provide cushioning and insulation, vital in industries like automotive and packaging. Additionally, pressure-sensitive adhesives (PSAs) contribute to efficient bonding, making them integral for adhesive-backed components such as labels and decals. Motson Graphics' adept use of these materials underscores its commitment to delivering precision-cut components and laminated finishes that meet and exceed the exacting standards of diverse industries.

Materials Available

In Motson Graphics' realm of die cutting and laminating services, the choice of materials is a critical factor in achieving precision and durability. The selection spans a spectrum of versatile options, including polycarbonate for transparent and impact-resistant applications, acrylic for high optical clarity and weather resistance, and polyester for chemical resistance and dimensional stability. ABS brings a balance of strength and machinability, while rubber and silicone offer flexibility and resilience, particularly in applications requiring elasticity and extreme temperature resistance. Foams, in both closed-cell and open-cell variations, provide cushioning and insulation, vital in industries like automotive and packaging. Additionally, pressure-sensitive adhesives (PSAs) contribute to efficient bonding, making them integral for adhesive-backed components such as labels and decals. Motson Graphics' adept use of these materials underscores its commitment to delivering precision-cut components and laminated finishes that meet and exceed the exacting standards of diverse industries.